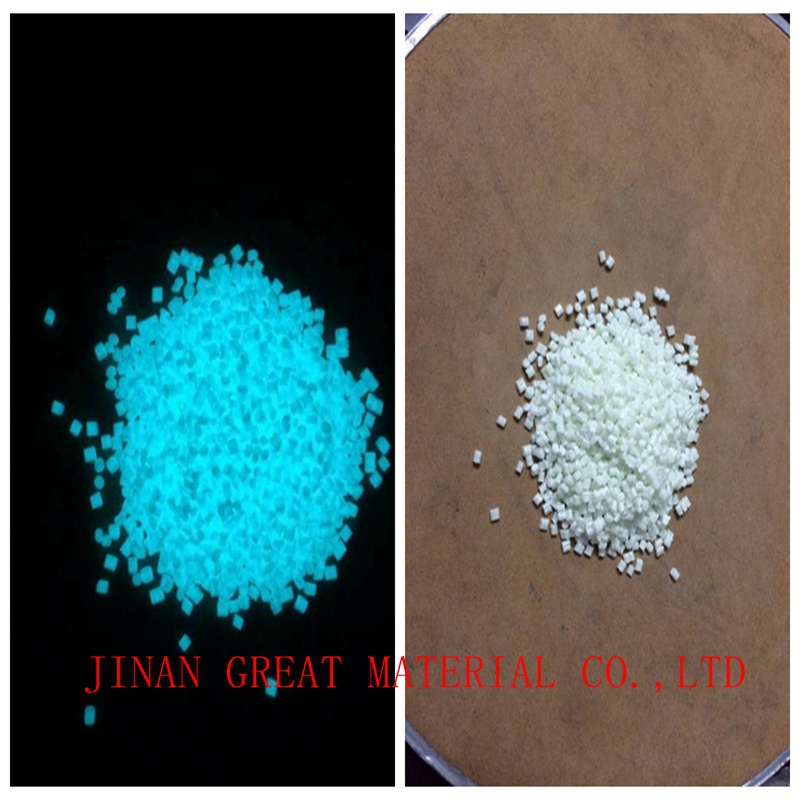

Luminous Plastic Master Batch

Luminous plastic mater batch is a man-made glowing particles, based on photoluminescent pigment and plastic master batch, such as PMMA,TPE,ABS,PC,PP,etc.

Luminous masterbatch can be used for extruding , blowing and injection craft .

Glow in the dark masterbatch can be used to produce luminous switch, helmet, flower pot, photo frame, key ring or other Luminous ark work and ornament.

Details

Luminous plastic mater batch is a man-made glowing particles, based on photoluminescent pigment and plastic master batch, such as PMMA,TPE,ABS,PC,PP,etc.

Luminous plastic master batch can be used for extruding , blowing and injection craft . Then the master batch can be used to produce luminous switch, helmet, flower pot, photo frame, key ring or other Luminous ark work and ornament.

|

Appearance |

Off white to Slight green color |

|

Materials |

PMMA,ABS,PE ,PC,PP ,PS,TPE and photoluminescent pigment |

|

Afterglow Color |

Yellow-green, Blue-green,Sky-blue |

|

Duration |

More than 8 hours |

|

Life |

More than 5 years |

|

Size |

2-3mm |

|

Brightness |

Can be adjust based on the addition of photoluminescent pigment ( 5%- 40% by weight) |

|

Shape |

Master batch particles |

|

Water Resistant |

Yes |

|

Storage |

Store in cool ventilated place, avoid direct sunlight |

How to make photoluminescent masterbatch?

1. Clean the interior of the extruder before manufacturing with the plastic master batch.

2. Keep the resin and pigment dry before the extruding process is started.

3. It is recommended to use a machine with twin hoppers and a distributive screw design. Use one of the hoppers to feed the resin and additives and the second for the photoluminescent pigment. Doing so will decrease the abrasion to the extruder surfaces.

4. Do not stir for a long time because this might darken the pigment/resin.

5. Keep the processing temperature 10 degrees higher than a normal run of plastic.

6. Clean the extruder again by running clear resin through until clear resin can be seen coming out of the extruder.

7. Use ceramic, glass or hard metal containers because the photoluminescent pigment will react to heavy metals causing discoloration.

8. Mix the photoluminescent pigment with liquid paraffin. Ratio of the liquid paraffin to the plastic particle is 1 -1.5% of the plastic particle.

Using the white mine oil makes the photoluminescent pigment stick evenly with the plastic.

| Contacts : | Li Sir |

|---|---|

| Phone : | 13706417022 |

| Email : | jngreat@foxmail.com |

| QQ : | 1344607103 |

| Skype : | greatlite |

| Wechat : | 13706417022 |

| Address : | 25# IFC,CBD, Jinan, China |